Key Publications and Presentations:

MTR uses SolvSep® membrane systems to dehydrate organic solvents widely used in the pharmaceuticals and fine chemicals industries.

Tetrahydrofuran is a popular solvent used in the production of a number of pharmaceuticals and fine chemicals, particularly hydroboration reactions and for reactions involving organometallic compounds such as organic lithium and Grignard reagents. To allow recycle and reuse, water must be removed to a very low level.

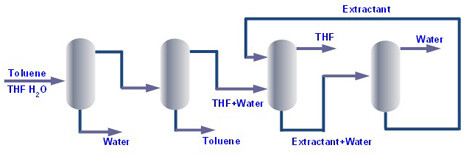

The figures below show recovery of THF and toluene after use in Grignard reactions. The traditional technology uses two simple distillation columns to separate some of the water and most of the toluene. The remaining water/THF mixture forms an azeotrope so extractive distillation with glycol or butanediol can be used. This requires two columns and a significant steam consumption, as well as producing a discharge water contaminated with THF and a portion of the extractant used.

Extractive distillation

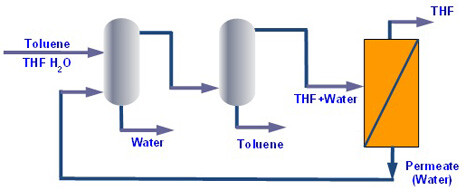

The alternative process is to replace both columns with a zeolite membrane unit. The membrane unit can produce 99.95 to 99.97% dry THF with a THF recovery of more than 95%.

Membrane dehydration

|

Item |

Traditional |

Membrane |

|

Steam (ton/ton products) |

2~2.5 |

1.2~1.5 |

|

Columns |

4 |

2 |

|

Yield |

85% |

>95% |

|

Extractant

|

Waste treatment, cause pollution

|

None

|

THF: from 95 to 99.97wt%, Capacity: 1,200 ton/year